The industrial production

The industrial production

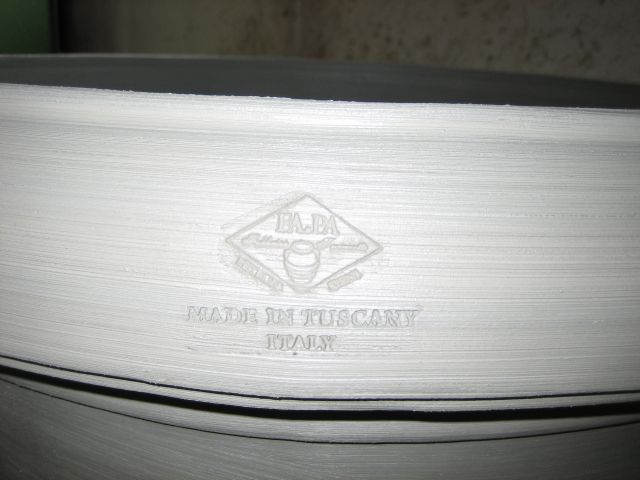

Made by press and chalk or metal moulds.

In this manufacturing process the vase is obtained through argil’s pressing on the chalk’s mould. Then, it is tore out blowing compressed air through some holes of the mould. As for the metal mould press, the vase is created by the pressing and the rolling of the mould. Afterwards, it is taken out thanks to an hydraulic oil. At last, the vase is refined and completed with a sponge bath.

Chalk press

Once completed, each vase is put into a wide kiln drying chamber where it stays for one or more days according to its size. Here the vase loses the damp it has inside otherwise it could not be cooked.

Dried vases are placed on a sort of big “trolley” and put into a wide oven. This oven can reach 985°C in 26 hours and it is cooled down in about a day and a half. Cooking and cooling’s times can change according to the material of which vases are made.

Cooking and cooling’s times can change according to the material of which vases are made.

When cooking is completed, vases are “stagnati” – as we say – which means that they are put into water to prevent “calcinelli” (little calcareous impurities which could damage the vase surface) from coming out.

In conclusion, vases are packed and ready to be consigned to our customers.